Temperature and Humidity Test Chamber

Temperature and Humidity Test Chamber

Product model :MH-1000CFactory direct offer.Environment Test Machine. OEM&ODM Service.

Specialized in environmental test equipments manufacturing, technology support.

MOESTEK MH series reach-in / compact environmental test chambers can help you test the influence of temperature on product performance, function and lifespan, and provide repeatable, certifiable, accelerating environmental simulation testing.

catalogue:Temperature and Humidity Test Chamber

Details Description

Advantages:

Standard Models:

| Model | Interior Dimensions(mm) | Exterior Dimensions(mm) | Temp. range | Volume(L) |

| MH-336A | 700×800×600 | 900×1750×1625 | -20℃ to 150℃ | 336 |

| MH-408A | 750×800×700 | 950×1750×1625 | -20℃ to 150℃ | 408 |

| MH-504A | 800×900×700 | 1000×1850×1625 | -20℃ to 150℃ | 504 |

| MH-600A | 850×900×785 | 1050×1850×1710 | -20℃ to 150℃ | 600 |

| MH-720A | 1000×900×800 | 1200×1850×1725 | -20℃ to 150℃ | 720 |

| MH-800A | 1000×100×800 | 1200×1950×1725 | -20℃ to 150℃ | 800 |

| MH-1000A | 1000×10001×1000 | 1200×1950×1925 | -20℃ to 150℃ | 1000 |

| MH-336B | 700×800×600 | 900×1810×1625 | -35℃ to 150℃ | 336 |

| MH-408B | 750×800×700 | 950×1810×1625 | -35℃ to 150℃ | 408 |

| MH-504B | 800×900×700 | 1000×1910×1625 | -35℃ to 150℃ | 504 |

| MH-600B | 850×900×785 | 1050×1910×1710 | -35℃ to 150℃ | 600 |

| MH-720B | 1000×900×800 | 1200×1910×1725 | -35℃ to 150℃ | 720 |

| MH-800B | 1000×100×800 | 1200×2010×1725 | -35℃ to 150℃ | 800 |

| MH-1000B | 1000×1000×1000 | 1200×2010×1925 | -35℃ to 150℃ | 1000 |

| MH-336C | 700×800×600 | 900×1810×1625 | -70℃ to 150℃ | 336 |

| MH-408C | 750×800×700 | 950×1810×1625 | -70℃ to 150℃ | 408 |

| MH-504C | 800×900×700 | 1000×1910×1625 | -70℃ to 150℃ | 504 |

| MH-600C | 850×900×785 | 1050×1910×1710 | -70℃ to 150℃ | 600 |

| MH-720C | 1000×900×800 | 1200×1910×1725 | -70℃ to 150℃ | 720 |

| MH-800C | 1000×100×800 | 1200×2010×1725 | -70℃ to 150℃ | 800 |

| MH-1000C | 1000×1000×1000 | 1200×2010×1925 | -70℃ to 150℃ | 1000 |

Standard Temperature Ranges:

Type A: -20℃ to 150℃

Type B: -35℃ to 150℃

Type C: -70℃ to 150℃

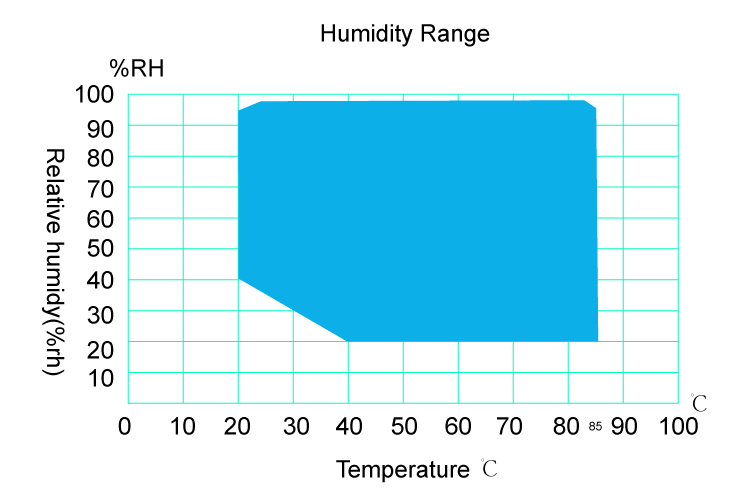

Standard Humidity Ranges:

20% to 98% (Maximum: 5% to 98%)

Detail display

Refrigeration system

Controller

TT-5166 True Color LCD Touch PLC Architecture Controller.Control by multiple groups of intelligent PID.

7 inch resolution: 800*480, 65535 true color with LED.

Temperature and Humidity Set Value(SV) and Practice Value(PV) display;

Chinese/English language switching display, true color touch input;

Program No, stage, remaining time, cycling numbers and running time will be displayed on the LCD;

Program and chart will be displayed on the LCD;

Fix and program mode will be displayed on the LCD;

The fault is automatically prompted, and there is a corresponding solution prompt.

Communication Interface

Safety Devices

Details Specifications

| Model | MH-1000C | ||||||||||||||

| System | Cool Balanced & Humidity Control System | ||||||||||||||

| Temp.Range | -75ºC~150ºC | ||||||||||||||

| Humidity Range | 20~98%R.H | ||||||||||||||

| Temp.constancy | ±0.5ºC | ||||||||||||||

| Humidity constancy | ±2.5%R.H | ||||||||||||||

| Temp.uniformity | ±2.0ºC | ||||||||||||||

| Humidity uniformity | ±3.0%R.H | ||||||||||||||

| Heat up time | -20ºC~+100ºC Within 35 mins | ||||||||||||||

| Pull down time | +20ºC~-20ºC Within 45 mins | ||||||||||||||

| Interior Dimensions(mm) | W | 1000 | |||||||||||||

| H | 1000 | ||||||||||||||

| D | 1000 | ||||||||||||||

| Exterior Dimensions(mm) | W | 1200 | |||||||||||||

| H | 2010 | ||||||||||||||

| D | 1925 | ||||||||||||||

| Interior material | Stainless Steel Plate(SUS 304) | ||||||||||||||

| Exterior material | Baked Painting Steel Or Stainless steel(SUS304) | ||||||||||||||

| Insulation material | Rigid polyurethane Foam and Glass Fiber Wool | ||||||||||||||

| Refrigeration system | Air Cooled( Water Cooled Type is option) | ||||||||||||||

| Hermetic compresssor, refrigeration system | Hermetic Compressor, Cascsde Refrigeration CFC free refrigerant | ||||||||||||||

| (HFC-507/HFC-23) | |||||||||||||||

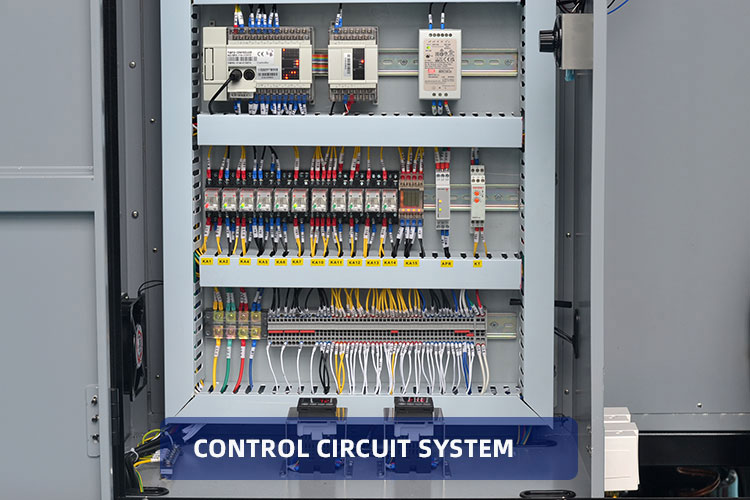

| Controllor | LCD Toch panel,Chinese or English display selectabile | PID Parameter 9set | |||||||||||||

| Operation model /Program or fix point rinning | Accuracy /Temp.:0.1%of F.S±1 dight | ||||||||||||||

| Memory capacity ,120programs,1200steps,all repeat999cycles,part 99 cycless. | Input /Temp.:Pt-100/Humidity:Pt-100or1~5VDCV | ||||||||||||||

| Comm.Port RS-232C or RS-485 (Software is option) | |||||||||||||||

| Safety Devices | No fuse breaker,over pressure, over heat and over current protectors for compressor, over temp.protector,over load protectorof fan,dry heat pr techto | ||||||||||||||

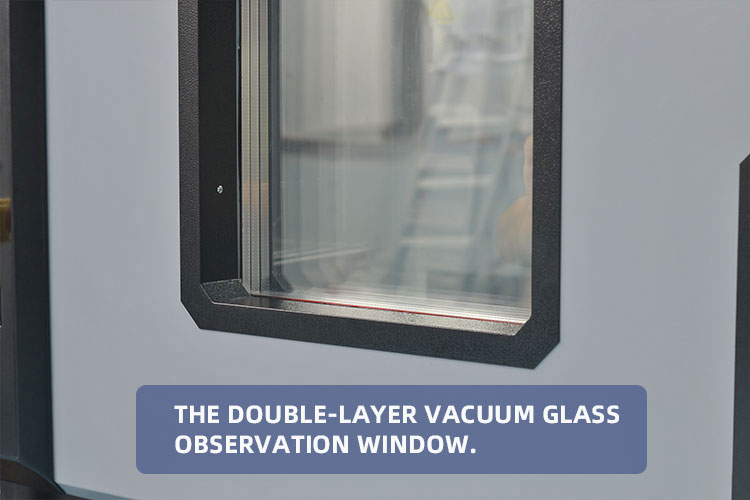

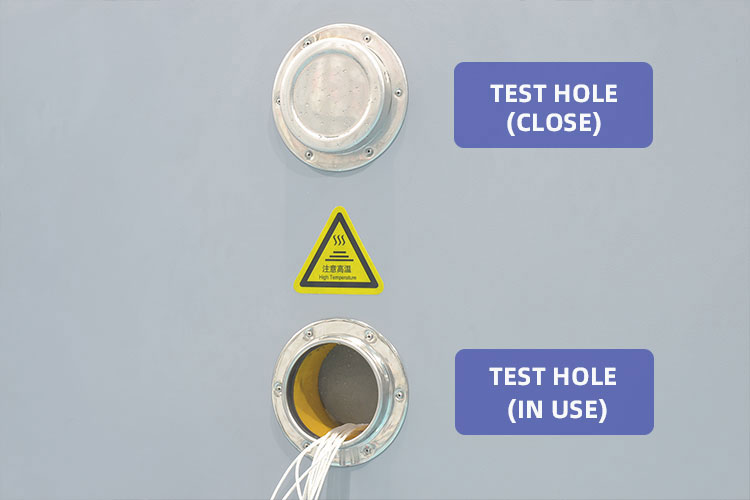

| Standard Accessories | Sightwindow*1,cable port(portΦ50mm)*1,shelves*2,chamberlamp*1,power cable 2m | ||||||||||||||

| Weight(Kg) | 700 | ||||||||||||||

| Ambient Temp. | -5ºC~+35ºC | ||||||||||||||

| POEWR | AC 380±10% 50Hz 3 phase 4 wires+Groud Wires | ||||||||||||||

| Explosive pressure relief device | when the pressure in the equipment or pipeline exceeds the safety valve pressure relief automatically open equipped with:Bursting disc,protective cover,sensor switch,exhaust fan function: | ||||||||||||||

| a.When the test items in the box explode,there is a pressure release pipe | |||||||||||||||

| b.Protect the test equipment from sudden air pressure damage | |||||||||||||||

| c.Protecting people | |||||||||||||||

| Ventilator | When the pressure in the tank exceeds the pressure of the safety valve and opens the pressure relief valve,the exhaust fan is automatically turned on. | ||||||||||||||

You might also like these

IPX5-6 Spraying Test

MW-S56BS-1000L

Salt Spray Chamber | MF-90C

MF-90C